内容

隐藏

Comprehensive Quality Assurance

we provide innovative solutions for automotive, medical, and electronic industries.

Injection Mold Quality Control

At GBM Mold Technology, our commitment to quality is ingrained in every step of our process.

Design Phase QC

- Utilize advanced CAD software like SolidWorks and CATIA for precise 3D mold design

- Conduct mold flow analysis using specialized software to optimize mold structure and injection parameters

- Hold design review meetings with senior engineering team

Material Inspection

- Perform spectral analysis on each batch of mold steel to ensure material quality

- Conduct hardness tests on steel materials

- Dimensional inspection of standard parts and accessories

Machining QC

- Implement “inspection at every process” principle

- Use high-precision CNC machining centers with tolerances up to ±0.01mm

- Conduct 100% dimensional inspection for precision components

Assembly/Testing QC

- Re-check precision of core components before assembly

- Inspect mold opening/closing clearance and parallelism

- Test cooling system sealing and ejector system smoothness

Final Inspection

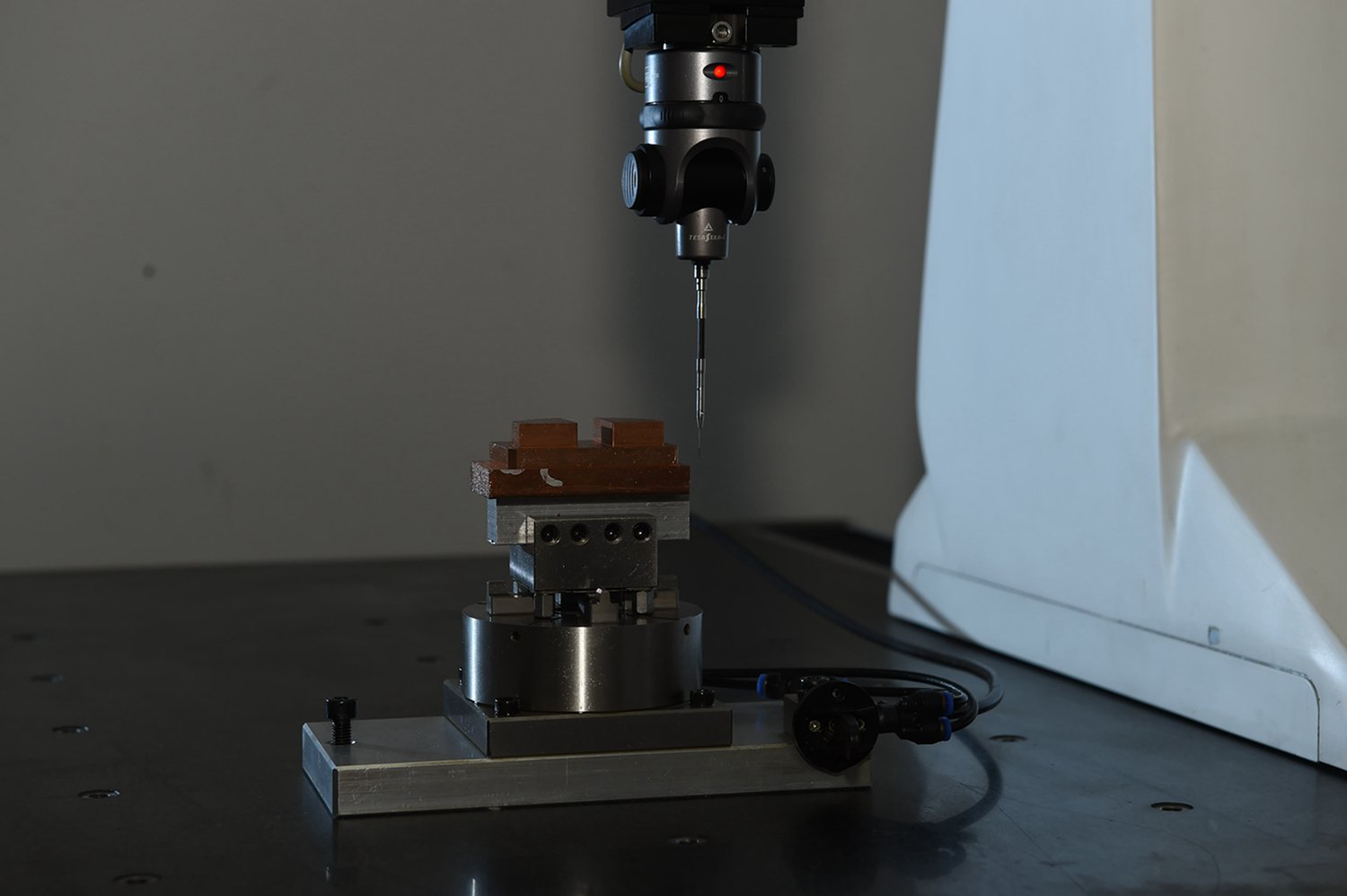

- Use coordinate measuring machines (CMM) for comprehensive inspection of core mold areas

- Conduct mold life testing to ensure it meets customer-specified production batches

Comprehensive Mold Quality Control Process

At GBM Mold Technology, we implement a rigorous quality control process throughout the mold manufacturing lifecycle to ensure the highest standards of precision and reliability.

1. Design Phase QC

- Utilize advanced CAD software (SolidWorks, CATIA) for precise 3D mold design

- Conduct mold flow analysis to optimize mold structure and injection parameters

- Hold design review meetings with senior engineering team

- Use CAM software (e.g., Mastercam) for efficient machining path planning

2. Material Inspection

- Perform spectral analysis on each batch of mold steel

- Conduct hardness tests on steel materials

- Dimensional inspection of standard parts and accessories

- Establish material traceability system

3. Machining QC

- 3.1 Rough Machining

- 3.2 CNC Precision Machining

- 3.3 EDM Processing

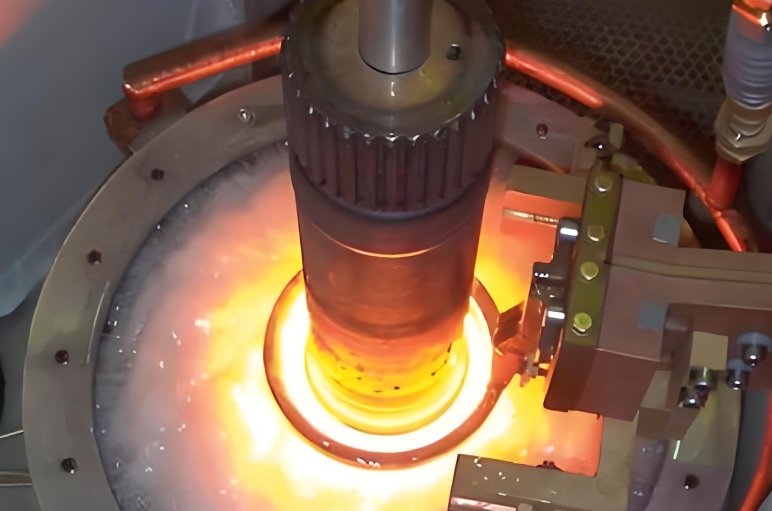

4. Heat Treatment QC

- Monitor heat treatment temperature and duration

- Post-treatment hardness testing

- Inspect for deformation or cracking

- Dimensional re-checking after heat treatment

5. Assembly and Testing QC

- Re-check precision of core components before assembly

- Inspect mold opening/closing clearance and parallelism

- Test cooling system sealing

- Check ejector system for smooth operation

6. Trial Molding QC

- Conduct trial molding, recording injection parameters

- Full dimensional inspection of first article samples

- Check product appearance for defects

- Perform product functionality tests

7. Final Inspection

- Comprehensive CMM inspection of core mold areas

- Conduct mold life testing

- Final appearance check after surface treatment

- Prepare detailed quality inspection reports

Injection Molding Quality Control

GBM's One-stop Service, Save Worry, Save Trouble, Save Cost

Material Preparation QC

- Strict selection of high-quality raw materials

- Precise control of material drying process

- Material blending according to product requirements

Production Process Control

- Real-time monitoring of injection parameters

- Regular inspections to promptly identify and resolve issues

- Strict control of production environment, especially clean room management

Product Quality Inspection

- Comprehensive inspection of first article samples

- Regular sampling inspection during production

- 100% final inspection before shipment

- Provision of FAI (First Article Inspection) and CPK (Process Capability Index) reports

Advanced Quality Assurance Equipment

- State-of-the-art coordinate measuring machines (CMM) for precise measurements

- Advanced vision systems for detailed surface inspections

- Specialized testing equipment for material properties and product functionality

At GBM Mold Technology, we implement a rigorous quality control process throughout the injection molding lifecycle to ensure consistently high standards in all our products.

1. Material Preparation QC

- Strict selection of high-quality raw materials

- Precise control of material drying process to avoid moisture effects

- Material blending according to product requirements

2. Mold Installation and Adjustment

- Precise mold installation ensuring alignment and sealing

- Adjustment of mold temperature to optimize molding conditions

- Mold trial run to ensure error-free operation

3. Injection Molding Parameter Setting

- Setting optimal injection temperature, pressure, and speed based on product characteristics

- Utilizing high-speed electric injection molding machines for high injection speed and precise metering

- Optimizing holding pressure time and cooling time to ensure product dimensional stability

4. Production Process Control

- Real-time monitoring of injection parameters to ensure production stability

- Regular inspections to promptly identify and resolve issues

- Strict control of production environment, especially clean room management

5. Product Quality Inspection

- Comprehensive inspection of first article samples

- Regular sampling inspection during production

- 100% final inspection before shipment

- Provision of FAI (First Article Inspection) and CPK (Process Capability Index) reports

Let's Talk

- Factory Address: 101, Building 1, Jiumo Tech, Shajing, Bao'an District, SZ, CN

- +86-0755-27691164

- +86 13632611848

- info@gbmmould.com

If you have a great idea, we can help bring it to life. We’ve done this before and enjoy becoming partners throughout product creation. From advising you through the mold sourcing process to delivering your new product to customers, we want to work with you every step of the way.