Insert Molding

Advanced Solutions for Metal-Plastic Integration

GBM Mold Technology leads the industry in insert molding solutions, offering cutting-edge technology for seamlessly integrating metal inserts with plastic overmolding. With over 20 years of experience and 2,000 successful mold projects, we deliver precision and innovation to automotive, medical, and electronic industries.

What is Insert Molding?

Insert molding is an advanced injection molding process that encapsulates metal inserts within plastic during the molding cycle. This technique creates a strong bond between different materials, enhancing product functionality, durability, and design possibilities.

Key Benefits of Insert Molding

- Enhanced product strength and durability

- Reduced assembly time and costs

- Improved electrical and thermal conductivity

- Increased design flexibility

- Weight reduction in final products

Applications of Insert Molding

Our insert molding technology finds wide application across various industries:

Automotive

Electrical connectors, bushings, and structural components

Medical Devices

Surgical instruments with ergonomic grips, implantable devices

Electronics

Connectors, switches, and sensors with integrated metal contacts

Consumer Goods

Appliance components, tools with metal reinforcements

Good understanding and engineering capability is the strong point

Advanced insert mold design and manufacturing

Material compatibility analysis and optimization

Precision tooling for complex geometries

Comprehensive quality control and testing

Rapid prototyping and production capabilities

Insert Molding Challenges and Solutions

Insert molding presents unique challenges that require expertise to overcome:

Insert Positioning

We use advanced fixtures and robotics to ensure precise and consistent insert placement.

Material Compatibility

Our material experts select optimal metal-plastic combinations to prevent issues like thermal expansion mismatches.

Flash Prevention

Precision mold design and controlled injection parameters minimize flash around inserts.

Quality Assurance

We employ rigorous inspection processes, including X-ray and CT scanning for internal structure verification.

Our Insert Molding Process

- 1.Close communication for customer's detailed specification;

- 2. Mold Layout Drawing;

- 3. Part Analysis;

- 4. Quotation based on customer's requirement

1、Design Optimization

Our experienced engineers use advanced CAD/CAM software to design molds that ensure precise insert placement and optimal plastic flow.

2、Material Selection

We carefully select compatible metals and plastics to achieve the desired mechanical and electrical properties.

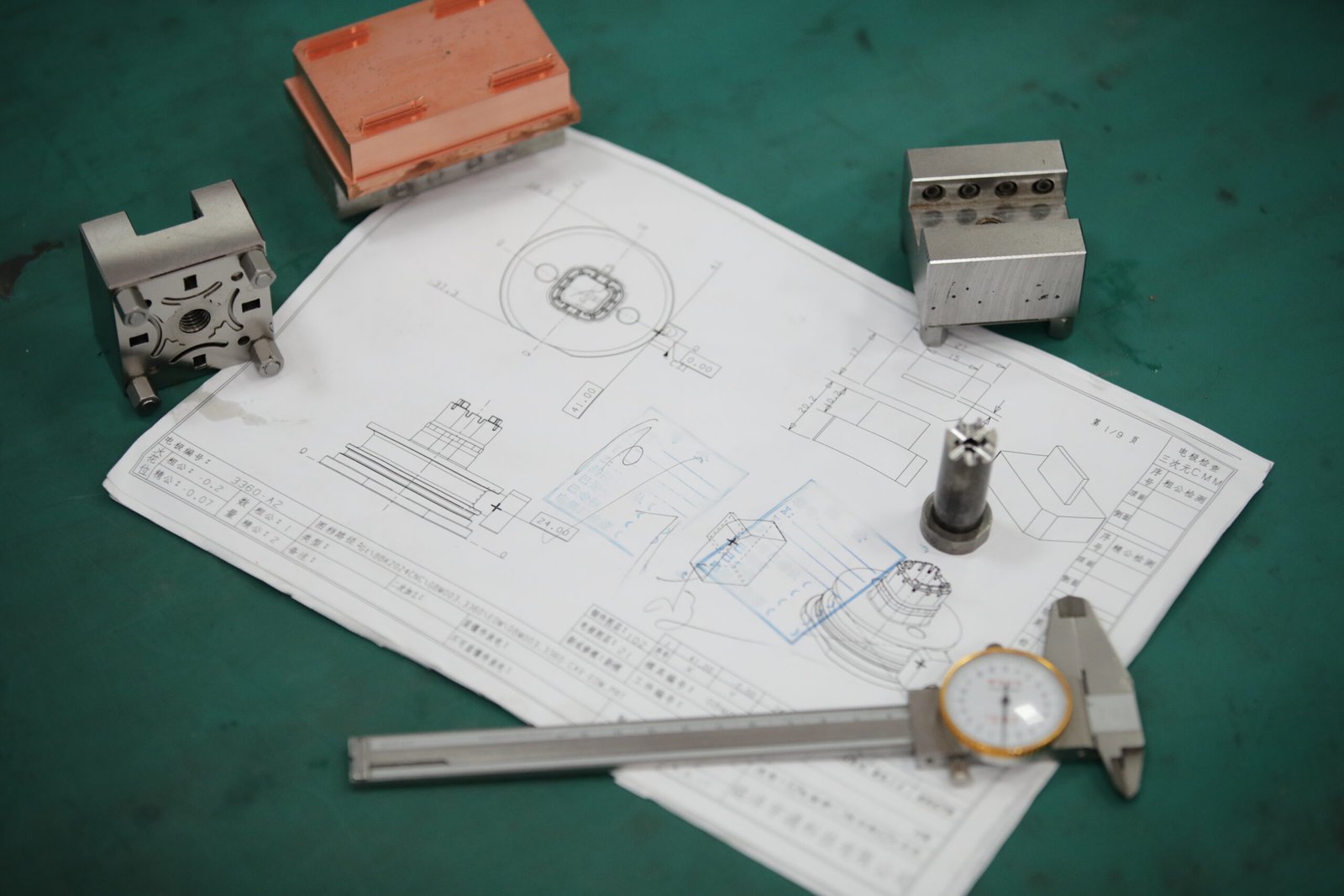

3、Precision Machining

Utilizing our state-of-the-art CNC machines, we create high-precision mold cavities and cores.

4、Insert Preparation

Metal inserts are carefully prepared and positioned in the mold using advanced fixtures and robotics.

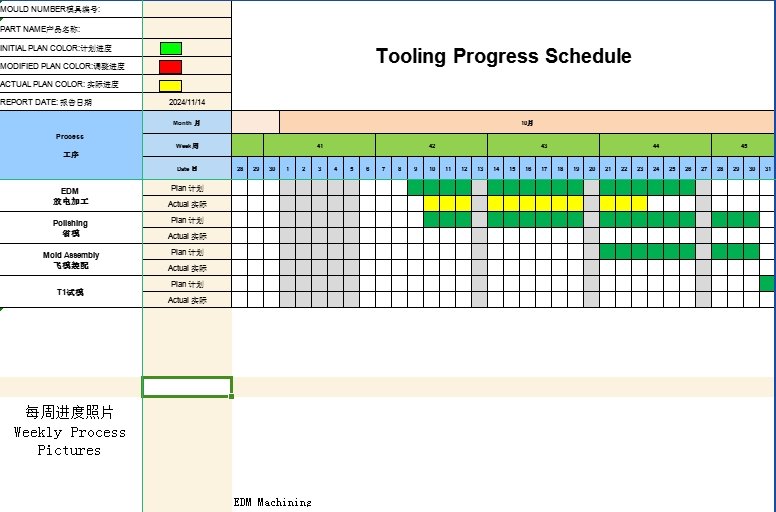

5、Project Management

Our high-speed injection molding machines precisely inject molten plastic around the metal inserts.

6、Weekly Process Report

Rigorous inspections, including CMM measurements, ensure each part meets exact specifications.

The GBM Advantage in Insert Molding

At GBM, we continuously innovate to push the boundaries of insert molding technology:

Multi-Material Inserts

Developing techniques for molding around complex, multi-material inserts.

Micro Insert Molding

Pioneering methods for integrating extremely small metal components in medical and electronic devices.

Sustainable Solutions

Exploring eco-friendly materials and processes to reduce environmental impact.

Quality Assurance in Insert Molding

GBM's One-stop Service, Save Worry, Save Trouble, Save Cost

In-process Quality Control

We perform checks at every stage of the molding process.

Advanced Measurement Techniques

Utilizing 3D CMM and vision systems for precise dimensional verification.

Material Testing

Conducting rigorous tests to ensure the integrity of the metal-plastic bond.

Production Monitoring

Real-time monitoring systems to maintain consistency across production runs.

The GBM Advantage in Insert Molding

Choose GBM Mold Technology for your insert molding needs and benefit from:

- Rapid Prototyping: Quick turnaround on prototypes to accelerate your product development cycle.

- Global Expertise: Serving clients across North America, Europe, and Asia with export-quality production.

- Cost-Effective Solutions: Optimized processes that reduce material waste and production time.

- Customized Support: Dedicated project managers ensuring seamless communication throughout your project.

Discover the GBM difference in insert molding technology. Let us help you bring your complex, multi-material product concepts to life with precision and efficiency. Contact us today to start your next insert molding project with a team that combines decades of experience with cutting-edge technology.

Let's Talk

- Factory Address: 101, Building 1, Jiumo Tech, Shajing, Bao'an District, SZ, CN

- +86-0755-27691164

- +86 13632611848

- info@gbmmould.com

If you have a great idea, we can help bring it to life. We’ve done this before and enjoy becoming partners throughout product creation. From advising you through the mold sourcing process to delivering your new product to customers, we want to work with you every step of the way.