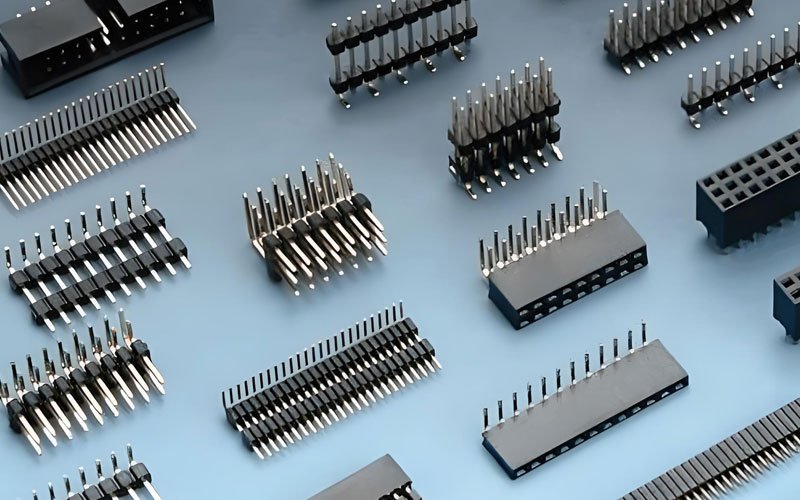

Connector Molds

Advanced Technology for High-Precision Electrical Components

GBM Mold Technology leads the industry in connector mold solutions, offering cutting-edge technology for the efficient production of complex electrical connectors. With over 20 years of experience and 2,000 successful mold projects, we deliver unparalleled precision and innovation to automotive, electronics, and telecommunications industries.

What are Connector Molds?

Connector molds are specialized injection molds designed to produce high-precision electrical connectors with intricate geometries and tight tolerances. These molds often involve complex designs with multiple cavities and slides to create the detailed features required for modern electrical connections.

Key Benefits of GBM's Connector Molds

- Exceptional precision for complex geometries

- High-volume production capabilities

- Reduced assembly time and costs

- Enhanced product reliability and performance

- Customizable designs for specific industry needs

Applications of Connector Molds

Our connector mold technology is crucial for various industries:

Automotive

Electrical system connectors, sensor housings

Telecommunications

Network infrastructure components

Electronics

Computer and mobile device connectors

Aerospace

High-reliability connectors for critical systems

GBM's Connector Mold Expertise

- Advanced connector mold design and manufacturing

- Precision engineering for multi-cavity molds

- Expertise in micro-molding for miniature connectors

- Comprehensive quality control and testing

- Rapid prototyping and production capabilities

Case Study: Innovative Solution for General Motors

We recently completed a groundbreaking project for General Motors, showcasing our expertise in complex connector molds:

- Challenge: Design and manufacture a mold with over 1,400 small inserts for a critical automotive electrical component

- Solution: Leveraging our advanced design capabilities and precision manufacturing techniques, we created a highly complex mold integrating all 1,400+ inserts

- Result: The mold was successfully tested in a single trial, demonstrating our unparalleled expertise and efficiency in connector mold production

This case exemplifies our ability to handle extremely complex projects with precision and efficiency, setting new standards in the connector mold industry.

Good understanding and engineering capability is the strong point

Over 20 years of industry expertise in complex mold structures

State-of-the-art manufacturing facilities with high-precision equipment

Experienced engineering team specialized in challenging connector designs

Proven track record with major automotive and electronics manufacturers

Commitment to innovation and quality assurance

Fast turnaround times, with many projects successful in first trials

Ready to Elevate Your Connector Production?

Contact our expert team today to discuss how our advanced connector mold solutions can enhance your product design and manufacturing process. With GBM Mold Technology, you’re choosing a partner committed to precision, innovation, and your success in the competitive electrical component market.