About GBM Mould

The preferred manufacturer of customized precision molds for Fortune 500 companies

Founded in 2006, GBM Mold Technology has established itself as a leading provider of precision injection mold and molding solutions. With over 20 years of industry experience and more than 2,000 successful mold projects, we deliver innovative and reliable products to meet the complex requirements of various industries.

13 YEARS OF complex mold manufacturing

Our Mission

To elevate the precision manufacturing industry while fostering the growth and happiness of our team and clients.

Our Vision

To become a trusted strategic partner for our clients’ success, a nurturing environment for our dedicated team, and a respected centenarian enterprise in precision smart manufacturing.

Our Core Values

- Customer Success: We prioritize our clients’ achievements and growth

- Employee Development: We nurture our team’s personal and professional growth

- Integrity: We conduct business with honesty and transparency

- Scientific Management: We embrace data-driven decision-making

- Innovation: We constantly seek new ways to improve our processes and products

Our Expertise

We specialize in complex mold structures and high-precision manufacturing, serving industries such as automotive, medical devices, and electronics. Our team of 50 professionals, including experienced engineers and project managers, ensures the highest quality in every project.

Our Commitment

At GBM Mold Technology, we are committed to:

- Delivering high-quality, precision molds and molded products

- Providing comprehensive services from design to production

- Ensuring rapid delivery with typical mold completion in 4 weeks

- Continuous innovation and improvement in our processes

- Building long-term partnerships with our clients and suppliers

Our Service

- We offer a one-stop service covering mold design, mold development, mold shell production, PCBA, and final product assembly.

Mold Design

Mold Design

Mold Making

Mold Making

Injection Molding

Injection Molding

Our Mold shop

- 38 sets injection machine for mass production in Facility,At least 9 times checking for every mold

CNC Area

EDM Area

Mold fitting

Daily guidance &team work

Three-dimensional inspection

Final checking &Shipping

Our Standard Work Process

- At least 9 times checking for every mold

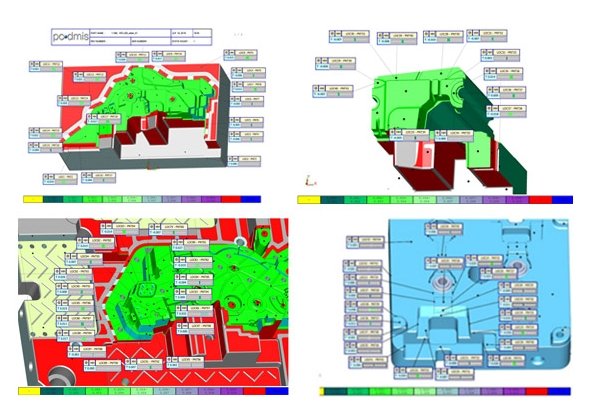

1. Mold Part Analysis

Professional analysis and suggestions shown with pictures enable the issues been easily understood.

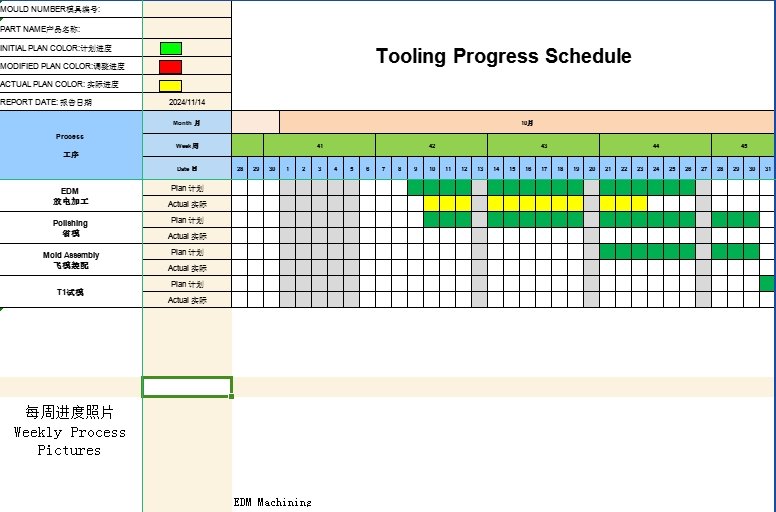

2. Project Management

Efficient communication.Take care the projects from design to delivery.

3. Weekly Process Report

Customers are always be updated by the project status

4. Mould Trial Pictures & Video

Customers are always be updated by the project status

5. Full CMM Report

We could provide d e tail measurement for m o ldedplastic parts.

6. Incoming Quality Control

All materials and components are checked (hardness, dimensions, etc) upon delivery to ensure they meet the project requirement.

7. In Process Quality Control

For mold making, every component or part will be checked at every manufacturing pro cess beforereleasing to the next step.

8. Final Quality Control

Before delivery, we will review the mold quality for fit, form, function.

Top Management Team

- 38 sets injection machine for mass production in Facility,At least 9 times checking for every mold

General Manager

Andy Gao

Engineering Manager

Thomas Peng

Production Manager

Jack Chen

Marketing Director

Joyce Wang

Get In Touch With Us!

- Email:info@gbmmould.com

- Tel:+86 13632611848

- WhatsApp/Wechat:+86 13632611848

- 101, building l, jiumo tech, shajing, bao'an district, sz, cn

We will get back to you within 2 hours.